PVDF (fluorocarbon) coating is one of the existing architectural coatings and is recognized as a protective organic coating. It can withstand damage to building panels for decades and maintain a beautiful color throughout. Since entering the market in 1965, fluorocarbon coatings have been accompanying buildings around the world for more than half a century and have always remained perfectly undamaged

PVDF (fluorocarbon) is a polyvinylidene fluoride (PVDF) material. The electronegativity of the fluorine atoms forms a very stable fluorocarbon bond, coupled with its unique molecular symmetry, which gives PVDF extraordinary stability, unique resistance to UV photolysis, and excellent insulation and mechanical properties.

Since 2021, PVDF (fluorocarbon) resin has gradually taken to the forefront, with raw material prices skyrocketing, and with the passage of time, it has become increasingly fierce. The high shortage and price have attracted countless users to compete and compromise.

PVDF (fluorocarbon) resin is mainly used in industries such as lithium batteries, photovoltaics, water treatment, fluororubber, and coatings. Against the backdrop of the country's dual carbon strategy, the strong demand for lithium batteries in electric vehicles has led to a shortage of this material in the lithium battery system. In the coating industry, PVDF (fluorocarbon) coatings are widely popular in many fields due to their excellent weather aging resistance, chemical corrosion resistance, and superior stability.

承诺·我们的初心

承诺·我们的初心

The skyrocketing price of PVDF (fluorocarbon) resin has sharply increased the price of fluorocarbon coatings, with some color coating factories using fluorocarbon coatings with low PVDF resin content to reduce costs. However, Baosteel Color Coated Plate firmly says "NO" to this behavior!

Baosteel, together with the coating supplier, guarantees that the fluorocarbon coating used adopts the patented PVDF resin formula (Kynar500 from Arcoma Enterprise in France) ® Or Hylar5000, Solvay Sulex, UK ®), Moreover, the PVDF resin content reaches over 70%, and inorganic ceramic pigments are used as pigments. Each new raw material must undergo a 10-year Florida exposure certificate before commercial use, thereby ensuring reliable product quality.

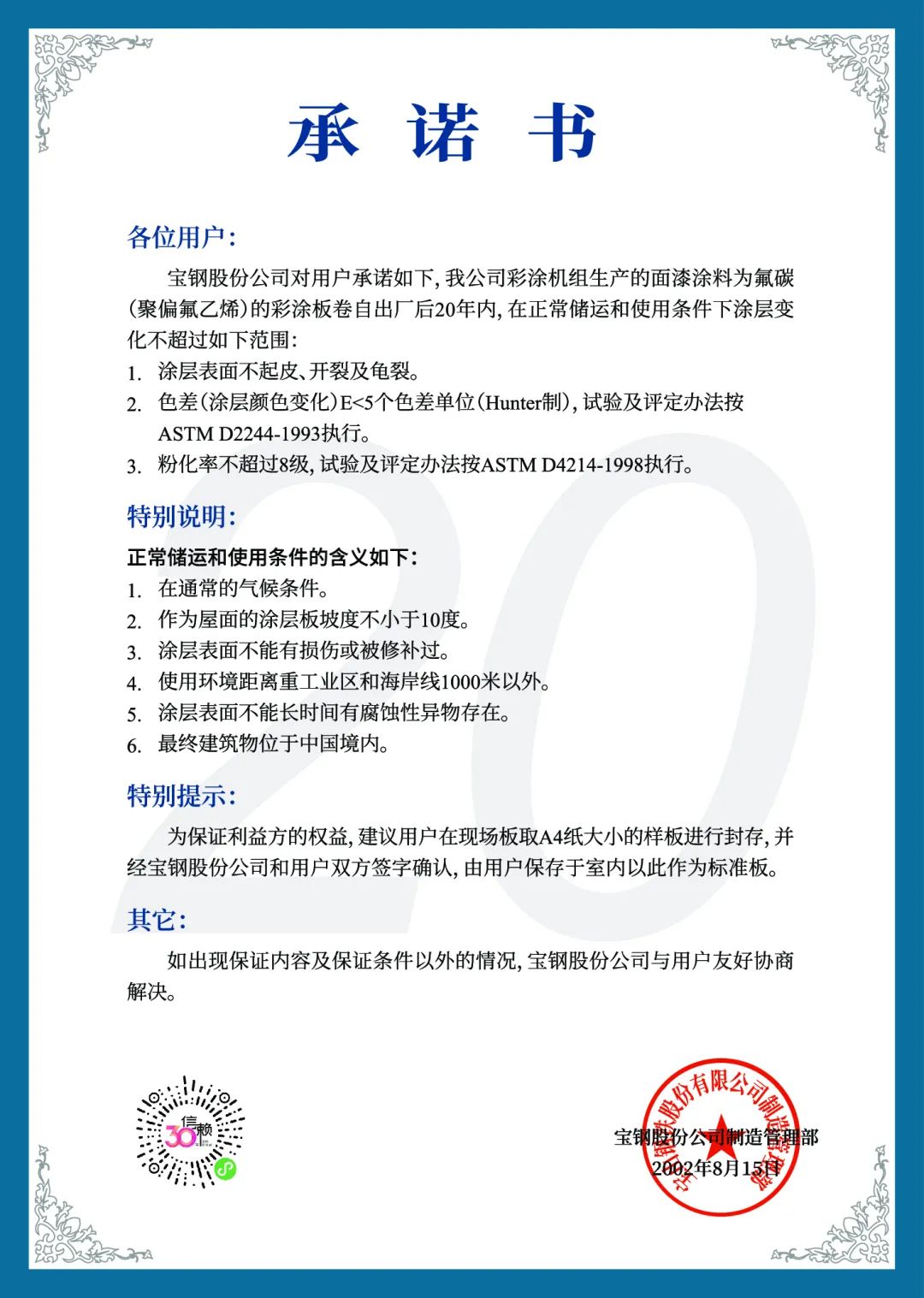

As an industry leader, Baosteel Color Coated Plate adheres to the principle of prioritizing user interests and promises to use fluorocarbon coatings with a PVDF (fluorocarbon) resin content of over 70%; PVDF (fluorocarbon) coating thickness not less than 23 μ M. Ensure the quality of every Baosteel fluorocarbon color coated plate and ensure a beautiful 20 year lifespan!

Commitment · Our Original Intent

The soaring price of PVDF (fluorocarbon) resin has sharply increased the price of fluorocarbon coatings, and some color coating factories are using fluorocarbon coatings with low PVDF resin content to reduce costs. However, Baosteel Color Coated Plate firmly says "NO" to this behavior!

Baosteel, together with the coating supplier, guarantees that the fluorocarbon coating used adopts the patented PVDF resin formula (Kynar500 from Arcoma Enterprise in France) ® Or Hylar5000, Solvay Sulex, UK ®), Moreover, the PVDF resin content reaches over 70%, and inorganic ceramic pigments are used as pigments. Each new raw material must undergo a 10-year Florida exposure certificate before commercial use, thereby ensuring reliable product quality.

As an industry leader, Baosteel Color Coated Plate adheres to the principle of prioritizing user interests and promises to use fluorocarbon coatings with a PVDF (fluorocarbon) resin content of over 70%; PVDF (fluorocarbon) coating thickness not less than 23 μ M. Ensure the quality of every Baosteel fluorocarbon color coated plate and ensure a beautiful 20 year lifespan!