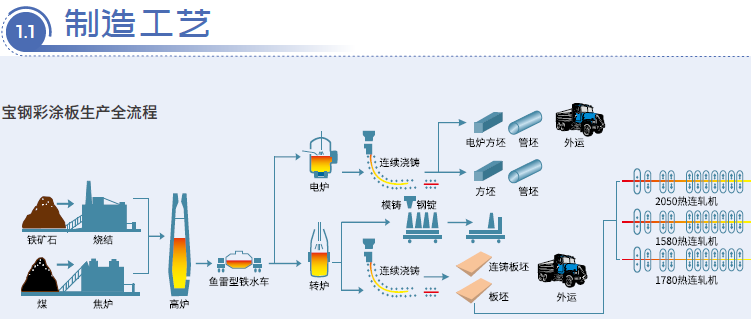

Recommended Examples of Special Color Coating in the Iron and Steel Metallurgy Industry

The color coating products used for the enclosure structure of the steel and metallurgical industry are different from ordinary building materials. The selection of materials must take into account the engineering geographical location, meet the requirements of high temperature and humidity resistance, strong acid and alkali resistance, hydrogen sulfide, ammonia, sulfur dioxide, nitrogen oxides, etc. generated by coking and sintering processes.

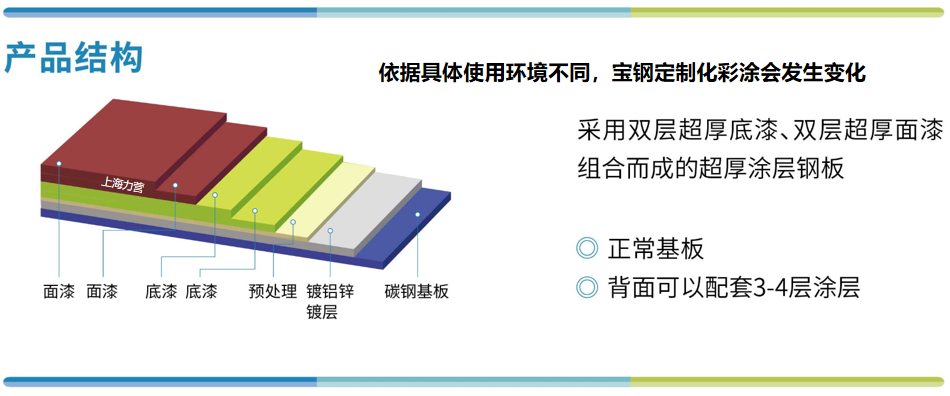

Different industries have their own characteristics, especially the steel and metallurgical industry, which has high temperature, high humidity, acid and alkali, and other highly corrosive media; There is a high requirement for the surface of the coating. The Baosteel color coated steel plates supplied by Liying meet the requirements of steel and metallurgical industry factories through customized methods for users.

Baosteel's professional customized color coating has excellent chemical resistance. While providing multiple colors to ensure the aesthetics of the building, it can withstand the invasion of the special high-temperature chemical environment in the steel and metallurgical industry. Even under the harsh tests mentioned above, the paint film can still maintain good condition.

(Baosteel Zhanjiang Steel)

1

Production process characteristics of the steel and metallurgical industry Corrosion environment | Ammonia gas, hydrogen sulfide composition, nitrogen oxides

The main corrosive substances in production are the production process characteristics of the steel and metallurgical industry. The main corrosive substances in production are harmful pollutants such as air and water, which are produced in various processes of the steel industry. The corrosive substances have a certain impact on the service life of equipment and factories.

The main pollutants generated by the coking and sintering processes of ironmaking include corrosive substances such as hydrogen sulfide, ammonia, hydrogen sulfide, sulfur dioxide, nitrogen oxides, etc. The main pollutants generated in the steelmaking process are as shown in the table, mainly particulate matter, and there are not many corrosive substances.

There are many and complex steel rolling processes, and corrosive substances mainly include acid mist, alkali mist, etc.

(节选部分污染物)

(节选部分污染物)

2

Environmental impact factors in the steel and metallurgical industry

Geographic environment | Coastal, UV light intensity

Specific environment of each factory building | Confirmation of surrounding polluting substances

Besides the production characteristics of the steel and metallurgical industry itself, what other areas do we need to pay attention to?

(Liugang Group)

Geographical location of the project

The main factors affecting the service life of color coated boards include ultraviolet rays in sunlight, water, and corrosive substances in the atmosphere. The ultraviolet rays in sunlight can cause the aging of the color coated board coating, and the higher the intensity of the ultraviolet rays, the stronger the aging effect. The ultraviolet intensity is mainly related to latitude and altitude, and changes with seasons, weather, ozone concentration, and other changes. The steel industry is easily distributed in coastal areas, and factors such as chloride ions and humidity in coastal areas also need to be considered.

Specific environment of each factory building

The selection of materials should be based on the climatic environment where the project is located and the service life of the factory building enclosure structure. Specific small environments should also be considered, including the distance from the coastline and whether there are polluting substances in the surrounding area.

Other factors

The steel industry is one of the key industries for environmental protection and governance, and some corrosive substances are also used in environmental governance. When constructing corresponding factories, it is necessary to consider the resistance of color coated boards.

three

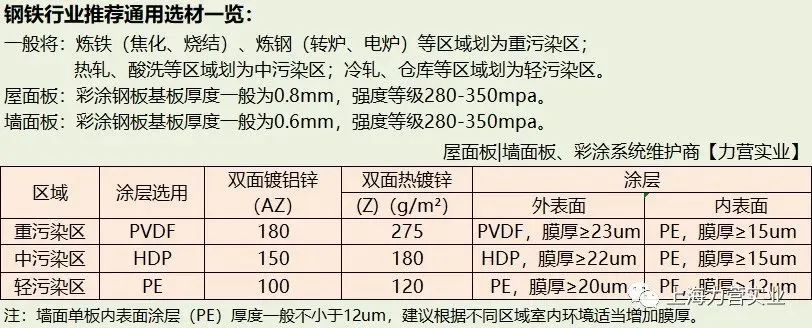

Recommendation for color coated plates for the steel and metallurgical industry

The environment in which the project is located

Select materials based on the climatic environment where the project is located and the service life of the factory building enclosure structure, including the distance from the coastline and whether there are polluting substances in the surrounding area.

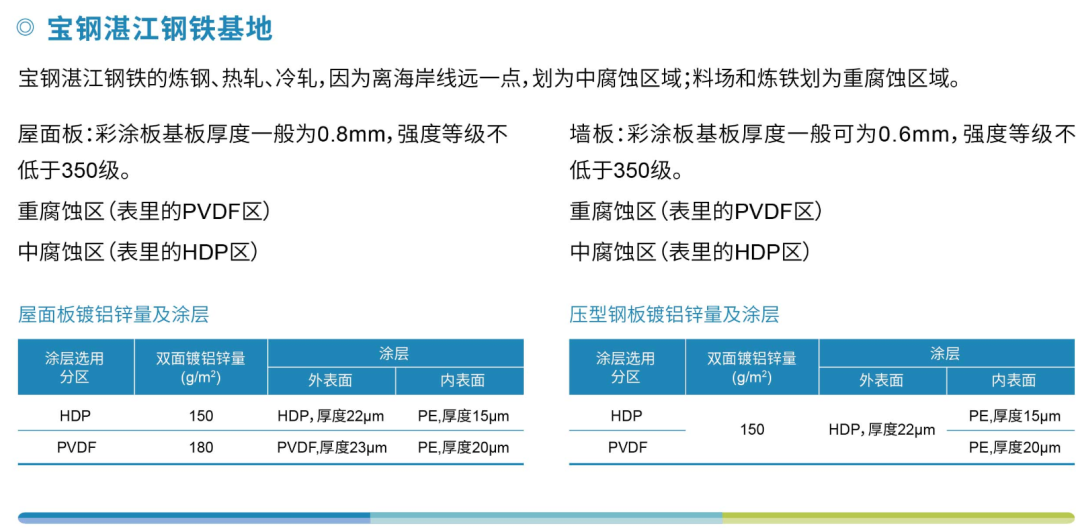

(Baosteel Zhanjiang Base)

Specific surrounding environment

The specific microenvironment of the factory also needs to be considered, such as whether there is local high temperature, whether there is local high humidity, and special attention should be paid to the high-temperature steam area. If there is a local microenvironment with high-temperature steam and sulfur dioxide, it is a highly corrosive location.

(Liugang Fangcheng Port)

The recommended material selection for Liugang Fangchenggang color coated steel plate is that the geographical location and process flow of Liugang Fangchenggang production base are basically the same as those of Baosteel Zhanjiang Steel, and the coating is selected with higher grade fluorocarbon types.

The steel and metallurgical industry is an industry with a long process and high investment, and the industrial process is relatively stable. The equipment update cycle is relatively long, and the requirements for the service life of factory buildings are relatively high.

four

Personalized recommendation for color coated plates in the steel and metallurgical industry

Money saving strategy | Paired use, higher cost-effectiveness

The specific service life required by the project is generally 50 years for industrial land in China. The service life for steel structure factory buildings is generally designed according to 25 years, and the recommended service life for the enclosure structure is around 25 years. It can also be shortened or extended according to the specific industrial environment and corresponding equipment renovation plans.

The specific usage environment needs to be consulted with the technical personnel of Shanghai Liying Industry.

(1) Recommend different coating combinations based on the environment in which they are used, to reach their service life and achieve the highest cost-effectiveness.

(2) Recommend substrates with different strengths based on the load requirements of different regions to improve safety performance and reduce investment. (3) Customized according to the requirements of single or composite sandwich steel plates, combined with plate shape, flatness, and processing performance, to improve cost-effectiveness. (4) Adjust the magnesium content of the coating appropriately based on the thickness and plate type of the engineering materials, in order to achieve the best combination of processability and notch corrosion resistance.

5

Color coated plates for the steel and metallurgical industry

Project Appreciation

(上海宝钢总厂)

Material selection: Baosteel PE275g/m2 TDC51D+Z Baosteel Baoshan Plant 1420 Cold Rolling Project started construction in 1995, which is an important project for improving Baosteel's product structure. It uses Baosteel hot-dip galvanized polyester color coated steel plate, brand TDC51D+Z, with a galvanizing amount of 275 grams per square meter on both sides. After 21 years of use, the film thickness reaches 19.2 micrometers, and the coating is well preserved without significant color changes. The overall condition is good.

(Baosteel Zhanjiang Steel) Material Selection: Baosteel PVDF/HDP150/180g/m2 THC500/550+AZ Zhanjiang Steel is the main battlefield of Baosteel's second entrepreneurship, striving to build the Zhanjiang project into a low-cost and efficient "dream factory". Considering the high temperature, high humidity, high chloride ion concentration, and strong ultraviolet radiation climate characteristics of Zhanjiang Donghai Island, as well as the full life cycle expenditure of the factory structure, the service life of the color steel plate enclosure is appropriately extended, It is possible to reasonably reduce the frequency of replacement during the production period and use relatively high standards of color coating according to different usage environments.

(Liugang Fangchenggang Base)

Material selection: Baosteel PVDF320/350 high-strength fluorocarbon 25 microns or 20 microns. In May 2012, the comprehensive commencement ceremony of the Fangchenggang Steel Base project was grandly held in the Qisha Linhai Industrial Park of Fangchenggang City. This project is a major project for the structural adjustment, layout optimization, and transformation and upgrading of the national steel industry, and is a key project for the new round of China's Western Development. The geographical location and process flow of the Fangchenggang production base at Liugang are basically consistent with those of Baosteel Zhanjiang Iron and Steel, and the coating uses higher grade fluorocarbon types. Strength level: 320 or 350 Coating type: aluminum zinc 75/75 or hot dip galvanized 140/140 Coating type: front fluorocarbon/back polyester Color: fluorocarbon 25 microns, cloud white 15 or 20 microns

We will continue to provide customers with better services, making every effort to deepen cooperation in various aspects such as resource and business expansion, high-quality service, and steel factory after-sales coordination among major steel mills. We will create an ecosystem of integrity, safety, convenience, efficiency, and win-win situation, and jointly paint a bright future for color coating!

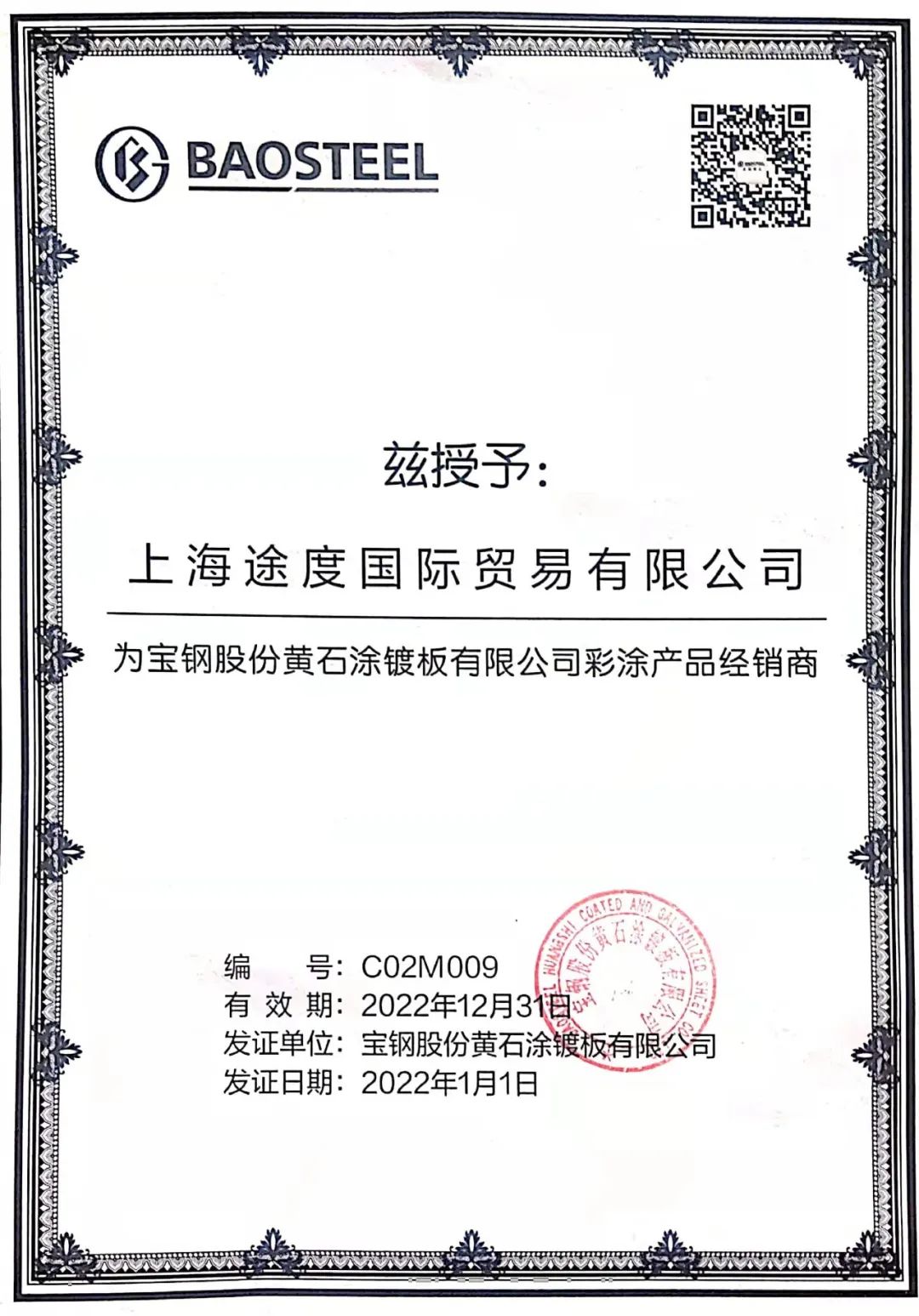

▲ Baosteel Corporation Agency Qualification Certificate

(Color coated products, aluminum zinc plated products, high aluminum zinc aluminum magnesium products)

▲ Baosteel Huangshi Agency Qualification Certificate

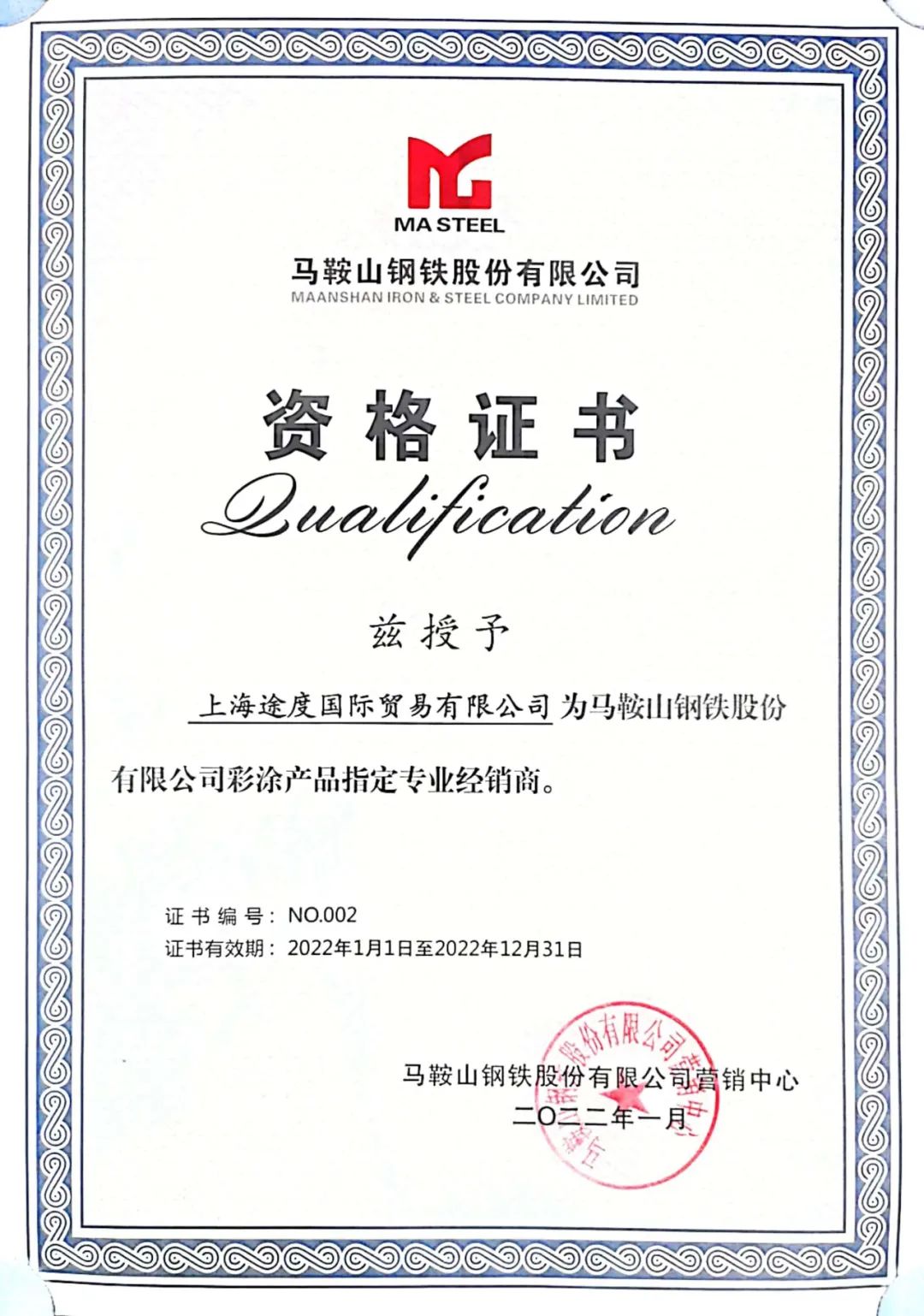

▲ Baowu Ma Steel Agency Qualification Certificate

Previous articles

▼

All three are from Baosteel, how would you choose?

Case Appreciation | Li Ying Supply Baosteel Case Appreciation

真伪辨别丨宝钢二维码如何验真伪!

Creating Beauty "Power", Aim "Camp" Heart Craftsman

Baosteel Color Steel Plate Consulting Center helps you understand and purchase coated steel products such as Baosteel, Baowu (Baosteel Qingshan), Baosteel Huangshi, Masteel Co., Ltd., and other high-end color steel plates - color coated plates - galvanized plates - aluminum zinc plates - zinc aluminum magnesium plates! Shanghai Liying Industrial Co., Ltd. is an authorized agent of Baosteel and Masteel, and the Color Coating Consulting Center is at your service! official account